Hollanders and Farbenpunkt combine decades of heritage in inkjet printer engineering with revolutionary chemistry in pigment inks and enter the market with a highly economical, efficient and user-friendly solution for a new era of sustainable narrow fabric production.

The narrow fabrics market has been challenged with long, inflexible and resource-intensive production processes. The Hollanders ColorBooster NF-DS in combination with Farbenpunkt’s PERACTOJet® inks enables new possibilities for the industry. From white to decorated tapes, ready-for-confectioning, in just one process line and in fewer production steps.

The Hollanders Take on Digital Textile Printing

Hollanders Printing Solutions is a Dutch printer manufacturer known for their robust, high-performing textile printing solutions, combining premium quality with low-cost production.

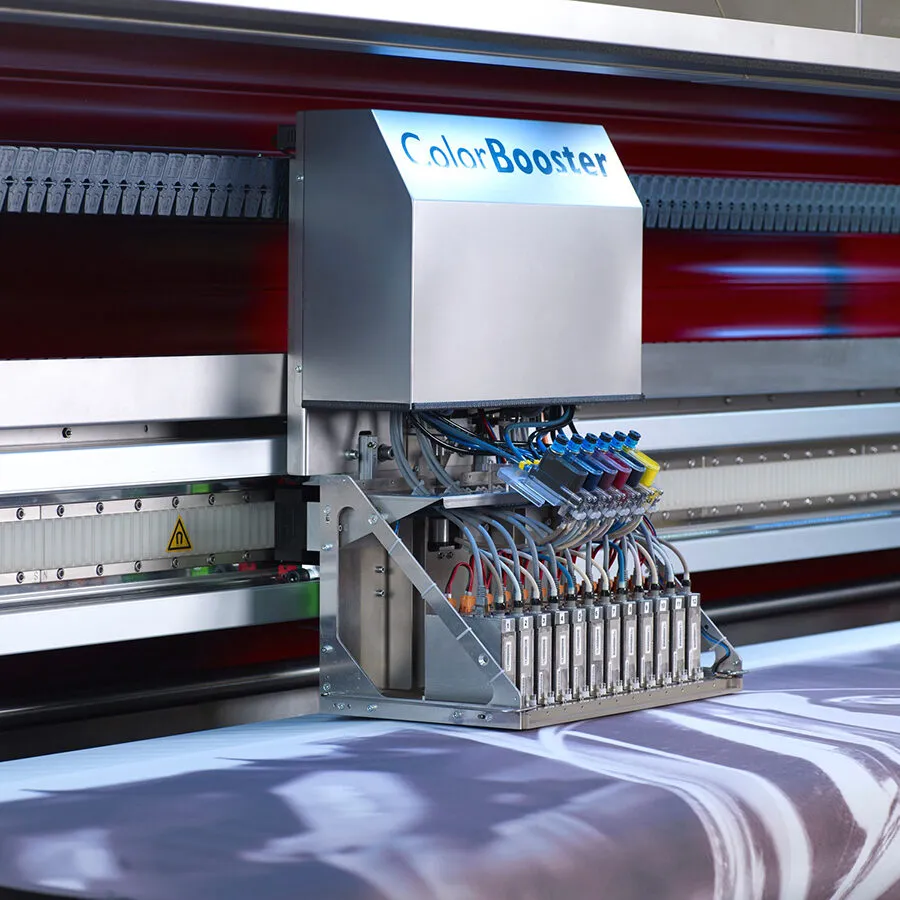

Based on their award-winning wide format printing system (ColorBooster), Hollanders introduces their new narrow fabric solution, the ColorBoosterNF-DS, an innovative system for the single or double-sided printing of rigid and elastic narrow fabrics.

Low-Impact Textile Coloration with PERACTO® Pigment Ink Technology.

Farbenpunkt GmbH, designs, develops and supplies textile colorants and is recognized for their innovative and process improving color solutions, enabling low-water, low-energy textile coloration.

In 2018 Farbenpunkt developed their change-making PERACTO® Pigment Ink Technology eliminating resource-intensive production steps from the digital printing process for textiles.

With the merge of their technologies and leveraging each others strength, Farbenpunkt and Hollanders, who have a close long-year relationship, set out to accelerate positive change for the narrow textiles industry by delivering an eco-friendly printing process without compromising product excellence.

Double-sided Inkjet Printing for Narrow Fabrics with a Reduced Environmental Footprint.

ColorBoosterNF-DS X PERACTOJet®

The ColorBooster NF-DS impresses with its exceptional print performance and innovative vertical printing capabilities.

It also has the unique feature of printing front, back and tape edges simultaneously, achieving impeccable accuracy, consistency and print quality on all sides.

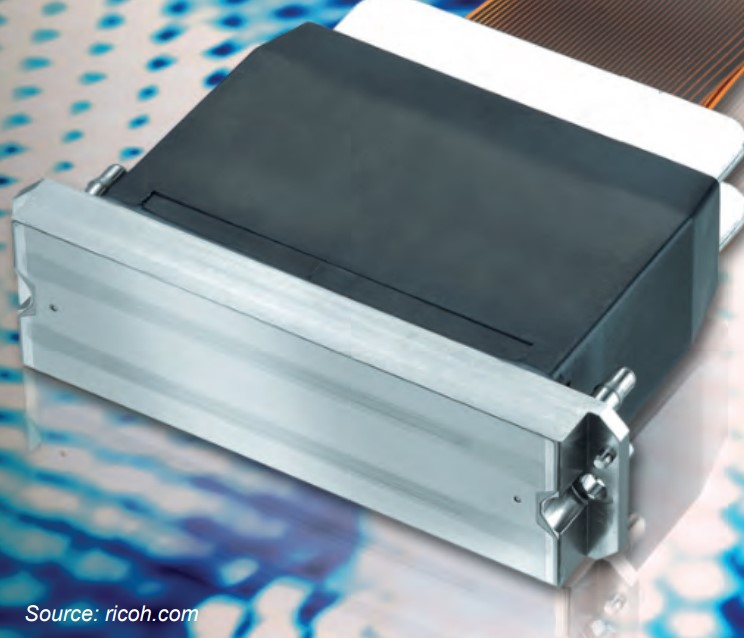

The ColorBooster NF-DS is equipped with industrial recirculation printheads, which can print up to four tapes in parallel.

The recirculation printheads keep the ink constantly circulating, preventing the ink from clogging any nozzles.

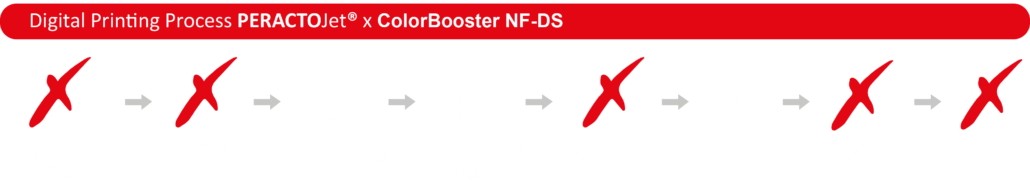

PERACTOJet® are water-based pigment inks with integrated binder capabilities, bypassing the need for a pre-or posttreatment process, on the majority of substrates.

Yet, they still achieve superior color properties compared to other pigment inks on the market.

PERACTOJet® enables a waterless printing process by eliminating washing and steaming processes from the production line, reducing the process to merely printing. pre-drying and curing:

PERACTOJet® inks even further simplify the production process and increase ease-of-use as they are suitable for both natural and synthetics fibers, as well as fiber blends.

In other words, only one ink and machine set up is required for the printing of a wide range of narrow textiles, increasing flexibility, efficiencies and time-to-market.

The ColorBooster NF-DS is equipped to handle both rigid and elastic narrow fabrics.

With it’s outstanding media transport system, the industrial printer can effortlessly manage the printing and handling of elastic tapes.

Furthermore, the machine is currently successfully utilized in the production of military webbings, with approved IRR specifications.

Download the product catalogue for further specifications.

For further information or project specific questions please reach.